Dynamic Capacity Planning 101: Turn Volatility into Strategic Advantage

By

Simon Leyland

·

7 minute read

By

Simon Leyland

·

7 minute read

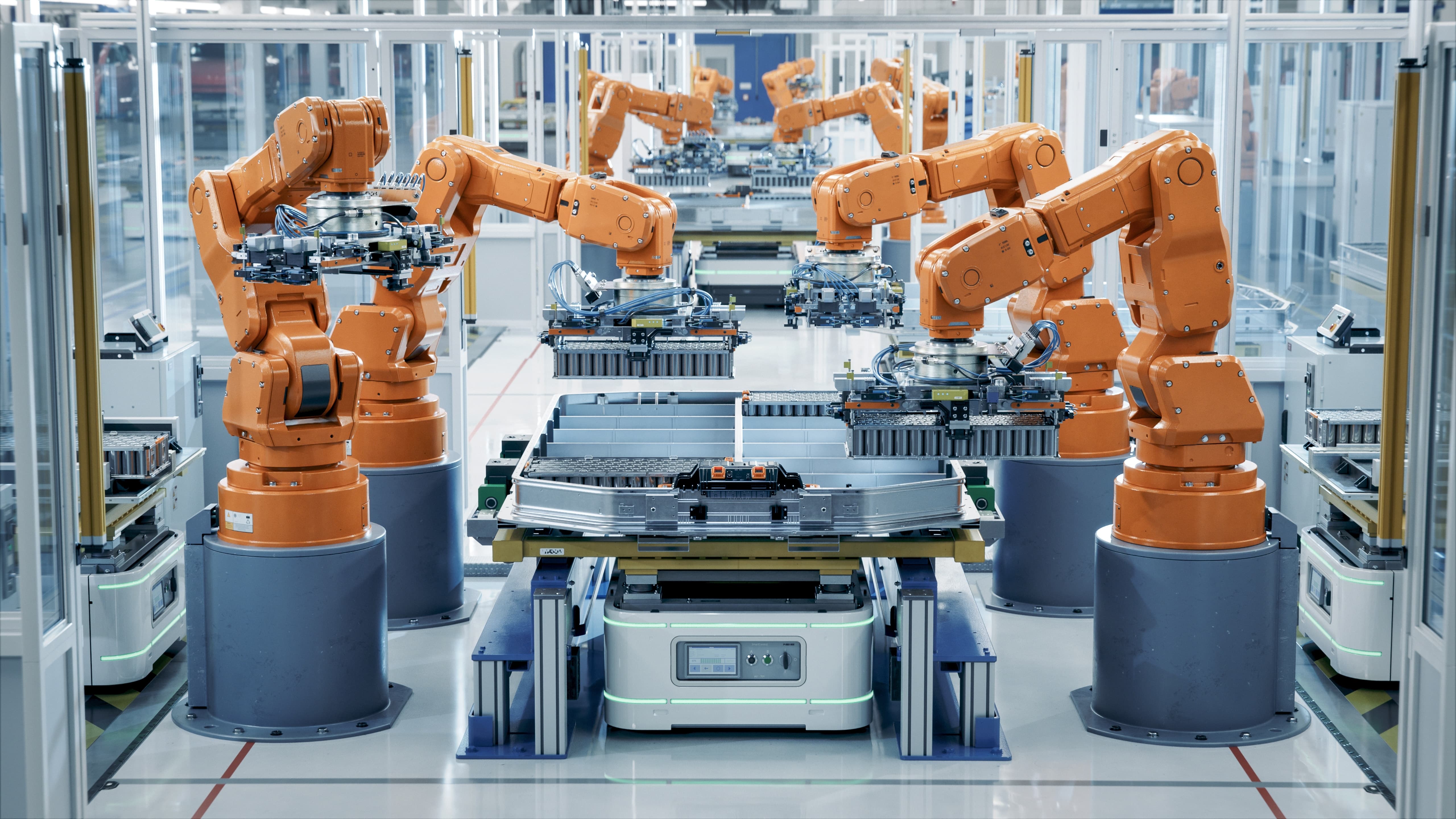

When volatility hits global demand or supply, factories feel the weight of production capacity limits. However, in product management, the strain shows up differently: CPOs and VPs of Product feel it when teams are misaligned and launch dates slip. They require a capacity planning view that maps human resources, roles, and time to the roadmap so they can make data-driven calls on scope, sequencing, and investment.

Through the use of adaptive product portfolio management tools, cyber-physical teams can deploy capacity planning strategies that maximize utilization, accelerate launches, and de-risk capital decisions.

In this guide, we will discuss the differences between production capacity at a manufacturing level versus capacity planning for product leaders, and how dynamic software elevates capacity planning from a static spreadsheet to a real-time, ROI engine.

First, let’s start with production capacity.

What is Production Capacity?

Production capacity is the sustainable rate at which a network of plants can produce saleable units. The production of these units falls within quality, cost, and delivery constraints, which are dictated by current assets, labor skills, materials, and process capabilities.

There are several layers of production capacity that manufacturers and engineers need to be aware of.

Levels of Production Capacity

Production capacity lives at multiple levels that are often assessed through actual output :

- Work center

- Manufacturing plant

- Supplier

- Global network

The level changes daily with maintenance, staffing, changeover time, yield, and software dependencies that gate hardware releases. Therefore, defining production capacity effectively requires separating theoretical maximums from what the system can reliably deliver in the real world.

For example, an automotive final assembly line rated at 60 jobs per hour (JPH) rarely ships 60 finished vehicles each hour. Planned maintenance, model changeovers, upstream shortages, quality checks, and micro-stoppages all reduce effective production capacity, which might average closer to 48–52 JPH over a full shift.

In a similar context, it is also important to consider the different types of production capacity:

- Design (or rated) capacity: The theoretical maximum under ideal conditions. Useful for benchmarking and high-level asset strategy, not for promising delivery dates.

- Effective capacity: The planned, sustainable rate that accounts for predictable losses-planned maintenance, standard changeovers, and typical scrap.

- Demonstrated capacity: The empirically observed output over a defined period, often trailing effective capacity due to real-world disruptions.

- Dynamic capacity: The living view that updates with real-time constraints (workforce availability, supplier slips, corrective maintenance) and is used for finite capacity scheduling and what-if simulations.

Understanding the levels and types of production capacity can help illustrate how changeovers, scrap, upstream material variability, and downstream bottlenecks reduce the demonstrated output you can count on in the sales and operations planning (S&OP) and master production schedule (MPS).

How Optimizing Production Capacity Changes P&L Outcomes

Capacity in a manufacturing sense is the bridge between demand and cost. If it’s misestimated, unit economics drift, margins compress, and inventory swells. If it’s dynamically managed, you absorb volatility at lower cost and capture upside without overextending working capital.

This not only improves immediate financial outcomes but also lays the foundation for sustained business growth by supporting long-term strategic planning. The macro signal cited above (utilization below historic norms) implies untapped headroom that product leaders can monetize before investing in new lines or facilities.

How Production Capacity Translates to ROI

Production capacity improvements don’t just feel operationally better; they show up in financials quickly. Leading manufacturers that shifted operating-technology budgets toward cloud platforms, AI copilots, and digital twins reported measurable returns, cutting unplanned downtime by 18%, lifting OEE by 12%, and delivering the highest ROI among their digital investments in the period.

While your mileage will vary, the mechanism is consistent: predict constraints earlier, simulate alternatives, and execute with fewer surprises. Many of these strategies are designed to improve production capacity, ensuring that manufacturing operations can scale efficiently:

- Fixed-cost absorption: Raising utilization spreads depreciation, overhead, and salaried labor over more units, improving gross margin without added headcount or CapEx.

- Working-capital efficiency: Shorter cycle times reduce WIP and finished-goods buffers, releasing cash while maintaining service levels.

- Revenue capture: Faster changeovers and finite capacity scheduling improve mix agility, letting you prioritize high-margin SKUs when demand shifts.

- Risk mitigation: Scenario analysis de-risks launches and supplier disruptions before they hit the line, avoiding expedited freight and premium labor.

In short, strengthening production capacity turns volatility into predictable throughput. The strategy raises output per hour, shortening lead times, and compounding margin as volumes scale.

Production Capacity vs Capacity Planning

Now, let’s discuss the differences between physical production capacity for manufacturers and capacity planning for product teams.

On one hand, production capacity deals with the physical elements of the manufacturing process, such as supply chain optimization and units of materials, while capacity planning focuses on human resources involved in building and launching the product (such as prototype development, product lifecycles, feature releases and sunsets, and time-to-market strategies).

In this next section, we’re going to take a closer look at capacity planning for product teams and how product portfolio management tools can keep product leaders and their teams aligned on complex portfolio timelines.

What is Capacity Planning for Product Teams

Modern products don’t live in silos. When software slips, hardware sits idle. This is where product leaders are necessary. Their role is to fill that gap with capacity planning.

Capacity planning in product management determines how much work extended product teams can realistically deliver within a given timeframe. Rather than physical output, capacity planning is anchored in human and resource allocation:

- Design

- Product development (build, prototype)

- Marketing teams

- Skills & time

- QA

The goal is to advance strategy by sequencing features and releases within the real limits of team capacity. Similar to production capacity, it matches demand to available capacity, only here the “units” are hours and skills, not machines and materials. It drives predictable delivery and fewer last-minute trade-offs.

Role of Digitalization in Capacity Planning

Digitization is well underway: 57% of manufacturing firms already employ cloud computing and data-analytics solutions.

Along with cloud computing, adaptive product portfolio management software is also used by product leaders, including CPOs and VPs of Product, to keep track of teams, roles, module depreciation, new feature roll-outs, time-to-market, and product development. Digital product management tools like Gocious give product leaders a 360 degree view of QoQ and YoY human resource capabilities and align them at the roadmap level.

Dynamic Software that Improves Capacity Planning for Product Teams

Static tools like spreadsheets freeze a moving target. Product roadmap software that aligns product leaders with capacity planning strategy and execution (like the alignment of hardware and software team schedules, feature releases, launch dates, and module sunsets) offers a living, people and priority-first model that leads to more data-driven decisions.

It enables VPs of Product to establish dynamic product roadmaps, effectively answering the question: “Can our teams deliver what we’ve promised, with the resources we have?”

At the portfolio level, adaptive product portfolio management software lets leaders:

- Build portfolio-centric roadmaps with team/role allocations per initiative, so planned work matches available bandwidth

- Use KPI Set Roadmaps to see how reprioritizing features affects time-to-market and team utilization, then compare to manufacturing capacity to avoid overpromising

- Apply modular architecture decisions at the roadmap level to reduce people-load (reuse) and ease cross-plant impacts

- Sync with tools like Jira/Power BI so effort estimates and burn continuously update the plan

See it in action: Discover how Gocious connects production capacity to strategy and execution with dynamic roadmaps. Book a 1:1 demo.

Connected Roadmap Intelligence for Cyber-Physical Teams

The root of capacity planning runs deep into the product management of both hardware and software teams. Its purpose is to determine if cyber-physical and cross-functional teams can deliver planned features or products within resource limits.

Software like Gocious exposes dependencies that consume team time (ex. firmware validation, compliance reviews, marketing readiness) and shows whether planned effort fits available hours by role.

CPOs who formalize this through connected roadmapping at scale reduce cross-functional churn and align on the next best decision, a practice explored in depth in our perspective on improving organizational alignment with dynamic roadmapping software.

Capacity Planning Dashboard: 360 Degree View of Resource Allocation

Advanced product management tools are necessary to determine if teams can deliver planned features or products within resource limits. For example, a capacity planning dashboard provides a strategic, portfolio-level view of roadmap commitments against team bandwidth. This shows leaders where to de-scope, shift timing, or rebalance resources to keep delivery realistic.

| Metric | Example Data | Description |

|

Product/Feature |

“AI-powered insights” |

Planned initiative |

|

Team |

Engineering (Backend) |

Resource pool |

|

Available Hours (per Q1) |

2,400 hrs |

Based on staffing levels |

|

Planned Workload |

2,600 hrs |

Estimated effort for all committed work |

|

Utilization |

108% |

Over capacity (same logic as factory) |

|

Actions |

De-scope features, hire, reprioritize |

Manage demand to fit resource supply |

Based on the capacity planning dashboard, resource allocation decisions can be made to break down limiting factors (like portfolio complexity), balance workload, and optimize delivery.

How to Turn Capacity into a Repeatable Advantage

Transform capacity planning from static to dynamic by identifying where limiting factors like time, human resources, and complexity are misaligned. Then rebalance scope, staffing, and timing in a living roadmap.

- Unify source of truth: Bridge the gap between hardware and software teams, feature releases and sunsets, product launches, and time-to-market estimates in one dynamic roadmapping tool

- Instrument constraints: Track where bottlenecks occur (ex. QA, security, localization, etc.) and tie them to features/releases on the roadmap

- Standardize what-ifs: Pre-build scenarios that vary scope, staffing, or timing, and compare against factory capacity

- Integrate KPI Set Roadmaps: Show execs how staffing or scope changes shift time-to-market, utilization, and margin

- Close the loop: Compare planned vs. actual hours and update velocity so future roadmaps reflect real team capacity

When product leaders effectively prioritize features, releases, or product initiatives to align with strategic goals while staying within team limits, they deliver on time, protect margins, and avoid overloading their teams.

Make Capacity Planning an Advantage with Gocious

In this guide, we discussed both production capacity for manufacturers and capacity planning for product teams.

In terms of capacity planning, successful strategies turn dynamic roadmaps into reliable commitments that sales and operations can trust. It helps VPs of Product and CPOs maximize ROI by focusing effort on the highest-value work, while also creating a repeatable planning rhythm that scales across portfolios and regions.

Gocious can visualize these capacity metrics across multiple product lines or portfolios, showing how planned initiatives exceed (or fit within) available team bandwidth.

It’s like an ERP for strategic decision-making rather than for production scheduling.

If you’re ready to learn how alignment across cross-regional and cyber-physical teams is possible through adaptive product roadmap software, schedule a custom demo with Gocious. Turn capacity planning into a competitive advantage all in one advanced product management platform.

Frequently Asked Questions

For manufacturers, which metrics best reflect production capacity utilization?

Production capacity utilization for the macro view; OEE to target equipment-level losses; throughput and cycle time for flow; and promise date accuracy to capture customer impact. Watch changeover time in high-mix environments and workforce capacity in skill-constrained operations. Tie all of these to financial KPIs so improvements translate directly into P&L outcomes.

What is capacity planning and why is it important to product leaders?

Capacity planning is conducted by product leaders, such as VPs of Product and CPOs to match plan product builds and launches successfully, matching resource allocation to the real people, budget, and timelines. Product leaders must use dynamic product portfolio management tools, including adaptive product roadmaps, to align their product teams to release commitments.

It matters to product leaders because it underpins investment choices (what to fund now vs. later), aligns brands/regions and hardware/software platforms, and ties plans to ROI and KPIs in a single source of truth.

How does dynamic product roadmap software help with capacity planning?

Dynamic roadmap software like Gocious models the capacity of human resources (teams, hours, roles, and speed) against planned features and releases. It lets product leaders run what-ifs (de-scope, shift timing, add staff) and instantly see impacts on time-to-market and investment, while staying aware of factory production capacity limits. The result: fewer surprises, realistic promises, and better absorption of fixed costs.

When should you invest in capacity planning versus optimizing what you have?

Start by measuring demonstrated team capacity against what the roadmap demands this quarter and next. First, close the gap with optimization: tighten scope, reduce handoffs, automate repetitive work, improve estimation, and rebalance work across roles and regions. If the backlog still outstrips an optimized plan over your horizon, then invest: add or upskill headcount, bring in specialized contractors, or form delivery partnerships. Use scenario planning to compare options on delivery timelines, quality risk, and total cost before committing.