Subscribe to our blog

Ready to improve your roadmapping process?

Curious about how Gocious can help your manufacturing team transform its Product Lifecycle Management strategy? Let’s schedule a call to explore!

Product Management Articles

Maziar Adl

Recent Posts

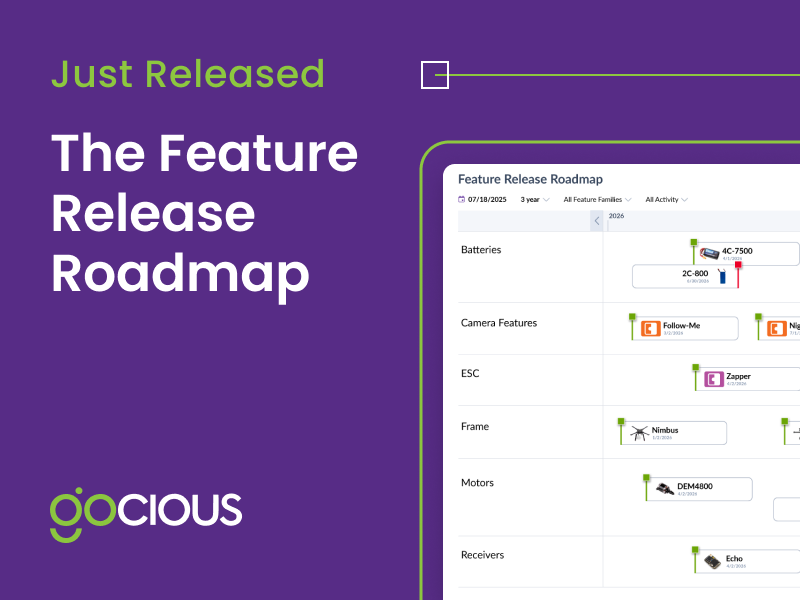

Gocious 2025 Year-in-Review: Notable Enhancements to Product Portfolio Planning Software

If 2025 had a singular theme at Gocious, it would be empowerment through innovation. We took valuable insights from our partners and transformed them into innovative roadmaps and software updates that truly empower global product leaders to move with speed without sacrificing strategic rigor or alignment.

How to Sunset a Product in Manufacturing with Examples

Most manufacturers can create a product launch plan quickly, but far fewer can outline how to sunset a product with that same level of clarity. A legacy product that lingers in the portfolio consumes capital, limits focus, and increases service complexity across regions and sales channels.

How the Product Process Matrix Improves ROI in Manufacturing

The product process matrix helps manufacturing managers determine whether their product strategy supports profitable scale or limits performance. This visual representation aligns product variety and volume with the process structure that supports them. It links product characteristics to the manufacturing process used on the plant floor so leaders can evaluate how their factories handle variation, cost, and throughput.

How Product Engagement Scores Drive ROI in Manufacturing

Manufacturers rely on clear, reliable indicators to understand how customers use their products, how adoption improves over time, and where product teams should focus their efforts. The product engagement score, often called PES, is one of the most valuable tools for capturing how many users engage with the product, how users interact with key features, and whether engagement trends support long-term growth.

The product engagement score measures adoption, stickiness, and expansion by combining three key metrics into a single view. This helps manufacturers evaluate user engagement with core features and understand whether users consistently return during a defined time period, such as daily, weekly, or monthly cycles.

Product Vulnerability Management: How to Assess Risk & Ultimate Checklist

Product vulnerability management has become a core leadership responsibility for manufacturers. As connected products combine hardware, embedded software, networks, and cloud services, even a single security vulnerability can pose significant risk to product performance, safety, and customer trust. Vulnerabilities can trigger recalls, exploited vulnerabilities in the field, breach events, and costly patch campaigns that disrupt roadmaps and consume resources.

Product Silos in Manufacturing: How to Break Them

Product silos continue to be one of the most costly and hard-to-spot issues inside modern manufacturing companies. As product lines expand across regions, variants, and software configurations, decisions often become fragmented across different teams. Each group optimizes within its own world, but no one sees the full picture. When this happens, organizations face missed revenue, higher costs, and slower reactions when customers or market conditions change.

How to Align Product Strategy with Company Goals in Manufacturing

For modern manufacturers, aligning product strategy with company goals has become essential for long-term success. When product roadmaps drift away from business objectives, organizations feel the impact through SKU proliferation, capital tied up in low-value variants, operational complexity, and declining margins. Misalignment creates a product portfolio that consumes resources without supporting revenue growth, market share, or measurable business outcomes.

Why Manufacturing Data Visualization Matters for Product Leaders

Manufacturing data visualization has become essential for product leaders who oversee complex portfolios in the manufacturing industry. Many organizations still view visualization as a set of disconnected charts or standalone dashboards, which results in slow decisions, misaligned priorities, and production lines that optimize locally without improving the portfolio as a whole.

Manufacturing Planning By Industry: Automotive, Industrial, Medical

Manufacturing planning has moved from an operational afterthought to a strategic weapon and competitive edge forproduct-led manufacturers. As product leaders commit to ambitious portfolios in various manufacturing industries, they must translate product roadmaps into factory plans that align product teams and promote strong time-to-market strategies. At the end of the day, margins are a big part of strategic manufacturing planning, and misaligned teams and missed launches can throw a wrench into ROI.

Product Operations vs Product Management: Key Role Differences

Role clarity between Product Operations vs Product Management is a structural choice that drives speed, quality, and ROI. As portfolios become cyber-physical and software-defined, blurred lines slow launches and inflate rework. Product leaders must define ownership, then execution follows suit.

The Product Leader's Guide to Manufacturing System Integration

Budget overruns, missed launch windows, and opaque quality trends persist when manufacturing system integration is treated as an afterthought.

8 Benefits of Product-Led Growth for Manufacturers

Executives weighing product-led growth vs sales-led growth are asking a pragmatic question: which model improves throughput and aligns cyber-physical teams without disrupting current revenue streams?